In its inaugural year, the newly revamped Fabrication Lab has quickly become a successful aspect of the Digital Corps. From 3D printing to laser cutting, The Fab Lab gives students a space to experiment, prototype, and bring ideas to life.

The Lab originally operated as a plastics prototyping and research lab with only a couple of 3D printers and some other very specific equipment. After the Lab Manager, Dr. Flowers, retired, it was used as a shared space between the School of Art and College of Architecture and Planning before The Digital Corps ultimately took it over. Now, The Digital Corps is aiming to expand access and training opportunities so that all students from any discipline can utilize The Lab to turn their ideas into something real.

For Aiden, a member of the Fabrication Team, creativity is what defines the space.

“My favorite thing about the Fab Lab is that it’s a place that really brings out people’s creativity. It gives you all the tools you need to turn an idea into a physical reality.”

Emily, another member of the Fabrication Team, agrees.

“One of my favorite parts of working in the Fab Lab is the amount of creative freedom I am given. Many times, when we are sought after for some sort of trophy or design, the client is searching for something unique, allowing me to add personal touches to each design while following the set requirements.”

This semester, the momentum in the lab has continued to grow. The team has been working on developing a series of “how-to” style Udemy courses. These courses make the Fab Lab technology accessible to anyone by providing step-by-step guidance that allows users to explore and master the equipment at their own pace.

Andrew, the Fab Lab Operations Manager, shared more about what the team is doing.

“We’re working on some eLearning courses for equipment training, making it easy for anyone to get certified on any of our digital fabrication tools. Right now, version 1.0 of laser cutter training is live on Udemy, with 3D printing and sublimation courses coming soon.”

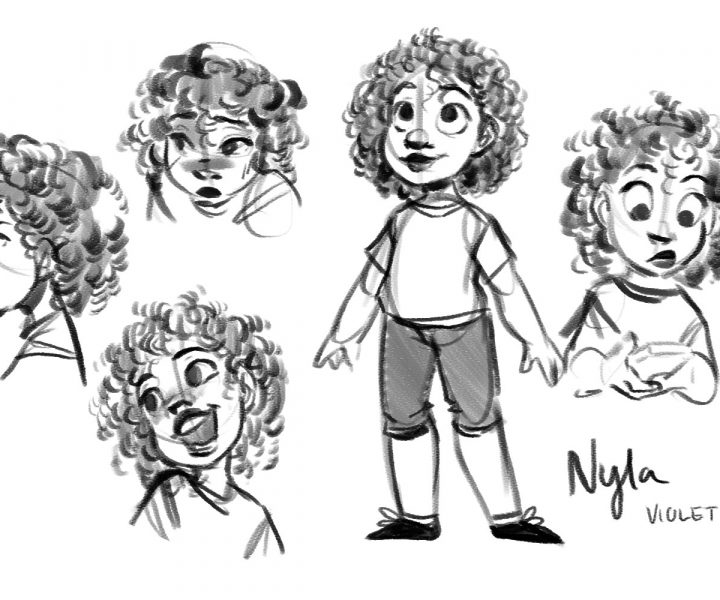

To continue building awareness on campus and highlight that the Fab Lab is a space for every student, the lab recently hosted its first tote bag workshop. The event invited students from all majors to get hands-on with Adobe Express and the lab’s sublimation equipment. Students came into the lab, created a design using Adobe Express, and then were able to use the heat press to transfer their design onto their tote bag.

“People from all over campus got to come in with a design and walk out with their own custom tote bag,” McKenzie said.

“Students made designs in Adobe Express, then we printed and pressed them onto the bags. It’s a super easy process, and we’re definitely planning to do more sublimation workshops in the future,” Arthur explained.

The workshop was a great success, and the Fab Lab is hoping to host more hands-on events like this in the future.

“Sublimation gives us the opportunity to customize a wide variety of objects from t-shirts to drinkware so definitely be on the lookout for more sublimation workshops in the future.”

If you’re interested in learning more about the Fab Lab, its equipment, upcoming workshops, or how to get involved, stop by AT 141 or check out its new website.